“We never give up on our patients. We are proud of our mission, which is to serve the most vulnerable.”

Your donation can help Dr. Clermont and our entire staff care for more patients than ever before.

Repairing our oxygen concentrator should have taken months. But thanks to the ingenuity of our staff—and their willingness to go above and beyond—we made this crucial repair in less than a week.

Medical oxygen is one of the most essential life-saving interventions used at SBH. It is used in a variety of ways, from supporting a steady heart rate to helping to administer anesthetics. We use a device called an oxygen concentrator to manufacture oxygen on site. Essentially, an oxygen concentrator takes ambient air—the air we breathe—and removes the nitrogen from it. The resulting gas is near-pure oxygen, which is then pumped into patients’ nose cannulas or face masks.

When in good working order, the oxygen concentrator can produce a virtually unlimited supply of the gas. However, in times when the oxygen concentrator has broken, we have had to purchase cylinders of oxygen in Port-au-Prince. The trip to retrieve the oxygen can take up to 10 hours, and the supply is finite.

In fall 2019, roadblocks from the civil unrest in Haiti made the road connecting Fond des Blancs and Port-au-Prince impassable. Our oxygen concentrator broke, and the roadblocks made it impossible to travel to Port-au-Prince to retrieve the oxygen cylinders our patients depended on. The situation was dire: although we had a few oxygen cylinders in reserve, our supplies were quickly dwindling. If we ran out, it would threaten the lives of dozens of patients.

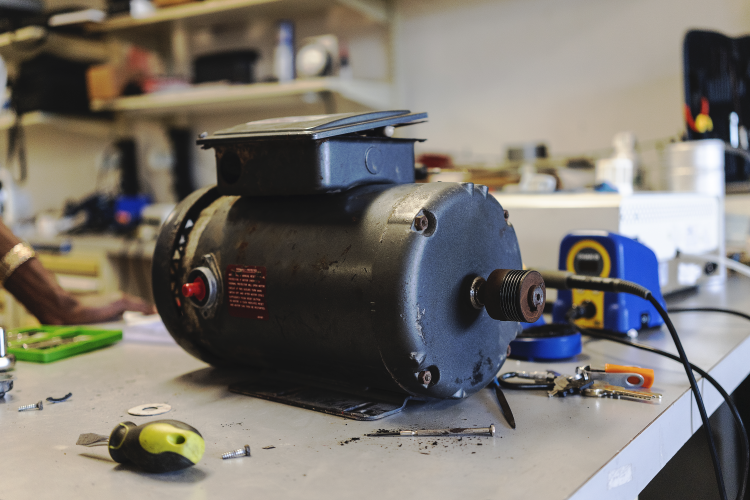

The compressor motor for the oxygen concentrator in the REPARE workshop.

Our facilities and biomedical engineering teams quickly dismantled the oxygen concentrator to identify the defective part—a switch inside the compressor motor had broken. Our biomedical technicians were able to create a temporary fix that got the oxygen flowing again, but there was no guarantee that the fix would last for more than a few days. The only permanent solution was to get a replacement motor to Fond des Blancs as soon as possible. The only problem was that the motor had to be sourced in the US, and shipping parts to Haiti can take months. The oxygen concentrator—and our patients—simply did not have this time to spare. So, our team took matters into our own hands.

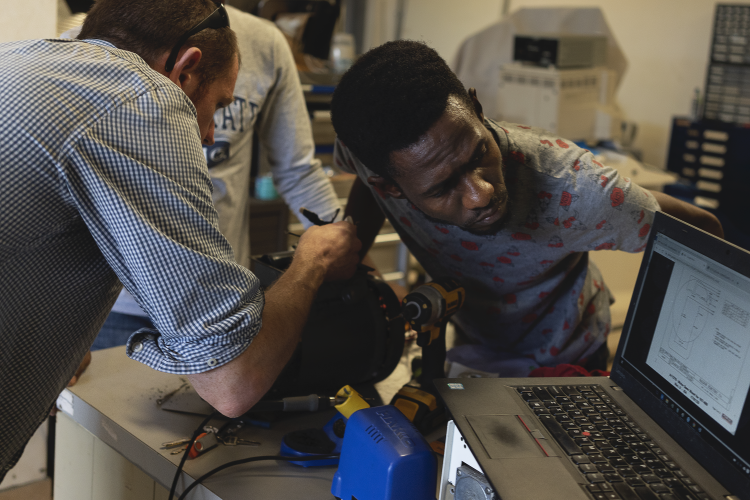

Fixing the compressor motor takes patience.

Putting the pieces together.

The replacement part for the oxygen concentrator traveled all the way from Boston to Fond des Blancs in a suitcase. A long but relatively quick journey.

We immediately ordered the motor and shipped it to HEI’s offices in Boston. From there, the 40-pound motor went into a suitcase and then into the hands of our newest staff member, who was moving to Fond des Blancs that same weekend. After hauling the motor and her own very heavy suitcases to the airport, this intrepid staff member flew to Port-au-Prince and was picked up by one of our ambulances, so she and the motor could be rushed to Fond des Blancs as quickly as possible. Thanks to a rare break in the protests, the car was able to quickly make the four-hour journey to the hospital. Once in Fond des Blancs, the biomedical and facilities teams immediately set to work installing the new motor. Within hours, the oxygen concentrator was pumping like new, ensuring an uninterrupted supply of oxygen to St. Boniface’s patients.

It should have taken months for the motor to travel the more than 2,000 miles from Boston to Fond des Blancs. But thanks to our team’s willingness to do whatever it takes to help our patients, our oxygen concentrator was humming again in no time.

Your donation can help Dr. Clermont and our entire staff care for more patients than ever before.